Boat Projects

An update on some of the projects being done on Pikorua while she is hauled out at The Boatworks.

They say "a boat is a hole in the water that you throw money into". Or that boat stands for "Bring Out Another Thousand". Either way it sounds about right as the bills start coming in for the work being done on Pikorua while we are hauled out at The Boatworks. She has done around 4500 nautical miles on the delivery trip so far so it was time for some much needed maintenance, warranty fixes, and with all the wonderful marine services available up here we couldn't resist treating ourselves to some upgrades.

Antifoul + Ultrasonics

"Antifoul"refers to the paint you apply to the hulls below the waterline to keep organic growth at bay. We commissioned 3 coats of antifoul to give it a good base to start with.

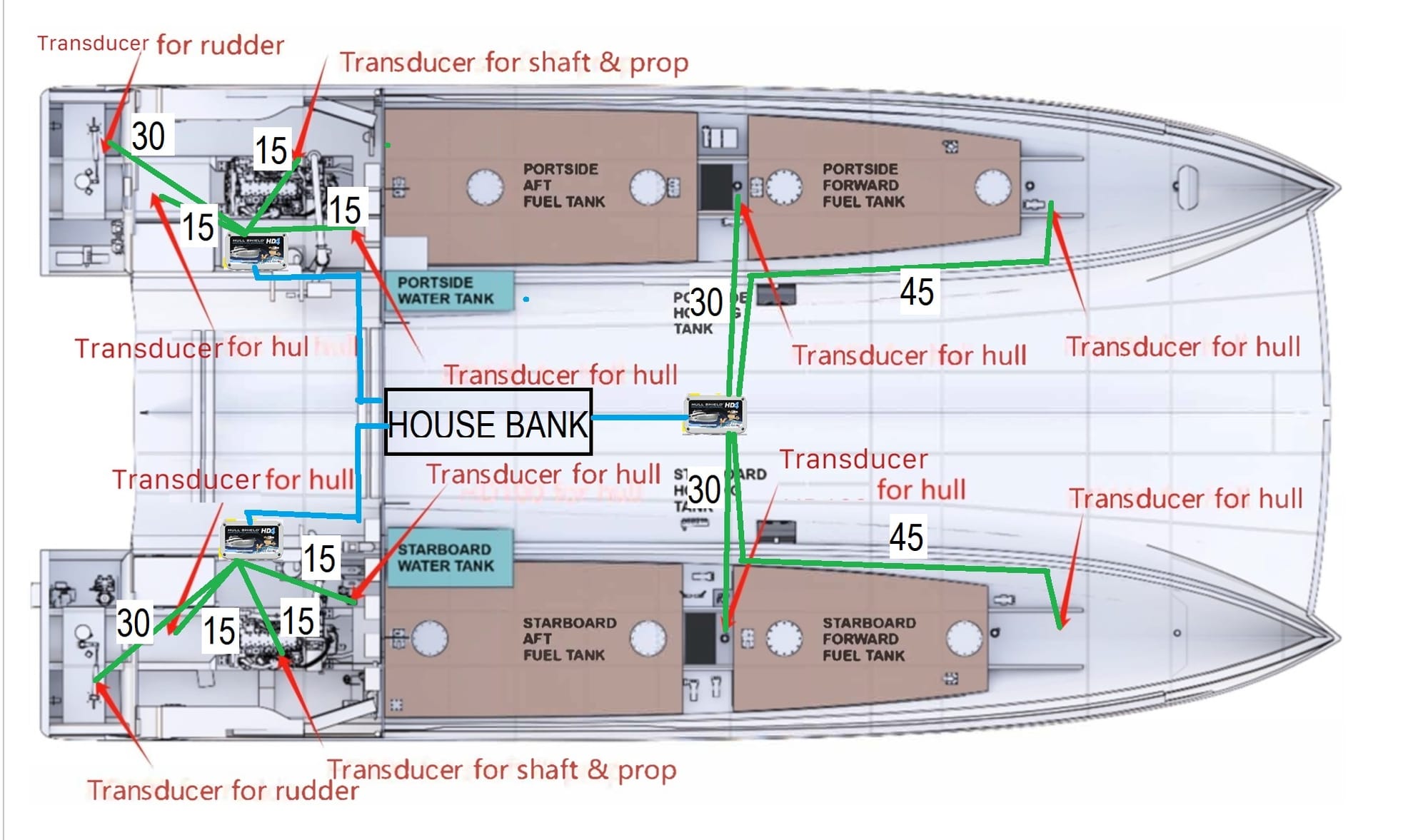

We also commissioned the install of an ultrasonic system from Aussie company CleanAHull. The idea with ultrasonic systems is that the sound vibrations stop algae growing which in turn stops the barnacles. The jury is out on how effective these systems are but I've heard good things from people whose opinion counts so decided to give it a go. If it performs as advertised it should pay for itself in 2 years.

We'll have four transducers installed in each hull, four transducers covering the engines and rudders, and another 2 for the bow thrusters.

Handrails

We've found our balance isn't as good as it was 10 years ago so we are adding/improving the handrail situation. Firstly, we are adding some to the salon roof so that you have something to hold on to while walking around the outside decks. Secondly, beefier handrails were custom designed to replace the skinny one installed in the flybridge stairs. These new ones will make it a lot easier to enter/exit the flybridge while underway.

Other Miscellaneous Stuff

- Covers: for outdoor cushions and tables, plus a mesh curtain for the back cockpit

- Detailing: getting the interior and engine rooms fully cleaned

- Running Gear: there were a couple of incidents involving fishing nets and ropes getting caught up with the propellor shaft while traversing the South China sea. Consequently the port side rudder and cutlass bearings were showing a little bit of movement. Not out of tolerance per se but enough to warrant replacement, just to be on the safe side. The starboard side was side done as well as a precautionary measure.

- Windscreen Wipers: adjusting the wiper installation so it covers more of the windscreen in front of the helm seats.

- Console Design: one of the things that was really bugging me was that our helm seats would not rotate properly because the arms were hitting the centre console. Plus the controls were not aligned properly. So, the console got a nip and tuck job, and the layout fixed up.

- Tweaking Electronics: fine tuning the setup of the CZone and Furuno systems.

- Fuel Filler Locker: their is a well in the fuel locker that was designed to contain any fuel spills but we found it was collecting water that subsequently got into the fuel tanks via the breathers. New drain holes are being added.

- Spray Rails: our spray rails didn't survive long in their battle with the waves. We'll have to go back to the drawing board on a new approach, but in the mean time we had to get the remnants of the old ones taken off.

On the warranty side, Granocean have approved a number of projects. We appreciate their great support, especially considering it is the Chinese New Year holiday at the moment.

What's Next?

We expect a couple more weeks for the work to be done before we can splash the boat. At that point the electronics guys can on board to test out systems that need the sea cocks open. After that we wait for a weather window and get Gary back to help us finish the delivery trip to Sydney.